VEAT-002 difüzyon pompası ünitesi vakum tüplü fırınlar, hassas laboratuvar ekipmanları ve küçük kapalı kaplar için tasarlanmıştır. 280L/s ana pompalama hızı difüzyon pompası ve 3L/s ön kademe döner kanatlı pompa ile donatılmıştır. Nihai vakum derecesi 2,5×10⁻⁴Pa'ya ulaşır ve KF40/KF25 çift egzoz portunun esnek bir şekilde değiştirilmesini destekler. Yağ buharı filtreleme, su sıcaklığı alarmı ve güç kesme otomatik koruma fonksiyonları ile donatılmıştır ve ISO 9001 ve IEC 60255 standartlarına uygundur.

Öğe Hayır. :

VEAT-002Minimum Sipariş Miktarı (MOQ) :

1 SetÖdeme yöntemi :

L/C, T/TFiyat :

NegotiatableÜrün oranı :

ChinaTedarik Yeteneği :

10 Set per monthKurşun zamanı :

90 DaysGeleneksel ambalaj :

PlywoodVeat-002 Yüksek Vakum Difüzyon Pompası Sistemi Ultimate Vacuum 2.5×10⁻⁴Pa Çift Portlu Kf40/Kf25

Ürün Tanıtımı

VEAT-002, yarı kapalı bir yapı ve akıllı sıcaklık kontrol sistemi benimser, bir No. 275 silikon yağ difüzyon pompası (ısıtma gücü 1kW) ve bir GS-1 döner kanatlı pompa entegre eder ve 20 dakika içinde kararlı yüksek vakum (≤2,5×10⁻⁴Pa) elde edebilir. Egzoz yolunu hızla değiştirmek için ekipmanın üstüne üç yollu manuel yüksek vakumlu deflektör vanası takılmıştır; dahili vakum solenoid valfi ve gaz tankı (1 saat sürekli vakum), hassas iş parçalarını korumak için güç kesildiğinde geri akışı otomatik olarak keser. PU hızlı fişli soğutma suyu arayüzüne (200L/saat akış) uyum sağlar, cam tüp sıcak eriyik tıkama, vakum kaplama ve sterilizasyon kabı vakumlama için uygundur.

Ürün Özellikleri

Uluslararası Referans Standartları

| Parametre | Şartname | Notlar |

| Pompalama Limanı | KF40 × KF25 (Çift Bağlantı Noktası) | Farklı ihtiyaçlara göre seçilebilir |

| Son Baskı | 2,5×10⁻⁴ Pa | — |

| Ana Pompalama Hızı | ≥280 L/s | Sistem tam yük altında |

| Ön Pompa Hızı | 3 L/s | Döner Kanatlı Pompa |

| Rezervuar Tutma Süresi | 1 saat | — |

| Difüzyon Pompası Gücü | 1 kilowatt | — |

| Difüzyon Pompası Yağ Tipi | 275. Sınıf | Silikon Yağı |

| Yağ Kapasitesi | 0,5 L | — |

| Ön Pompa Yağ Tipi | GS-1 | Yüksek Hızlı Vakum Pompası Yağı |

| Soğutma Suyu Limanı | 10 mm PU Boru Hızlı Bağlantısı | — |

| Soğutma Suyu Akış Hızı | 200 L/saat | — |

| Soğutma Suyu Sıcaklığı | 10℃–35℃ | — |

| Güç Kaynağı | 220 V AC | Güvenilir Topraklama Gereklidir |

| Toplam Güç Tüketimi | 1,8 kW | — |

| Ağırlık | Yaklaşık 105 kg | — |

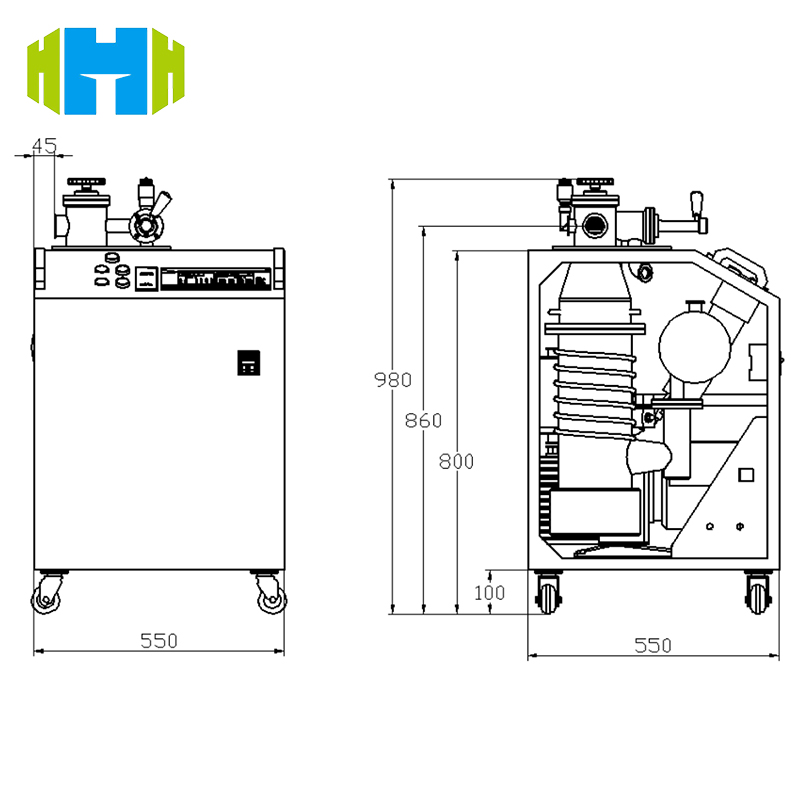

| Boyutlar (G×D×Y) | 550×550×980 mm | — |

| Pompalama Limanı Yüksekliği | Zeminden 850 mm | — |

Ürün Kullanımları

Test nesneleri ve muayene öğeleri

Test nesneleri: vakum tüplü fırın haznesi, yarı iletken kaplama ekipmanı, tıbbi sterilizasyon kabı, laboratuvar kütle spektrometresi.

Muayene kalemleri:

SICAK ETİKETLER :