HJ0615 Evsel elektrik iletişim borusu aşınma direnci test tasarımı, IEC60335-2-2 güvenlik standardına (Madde 21.102) uygundur, Destek emiş boruları, temizlik ekipmanı boruları, çamaşır makinesi su boruları, vb. ve milyon günlük aşınmaya dayanıklı sirkülasyon halkaları.

Öğe Hayır. :

HJ0615Minimum Sipariş Miktarı (MOQ) :

1 SetÖdeme yöntemi :

T/T, L/CFiyat :

NegotiatableÜrün oranı :

ChinaTedarik Yeteneği :

10 set per monthKurşun zamanı :

30 daysGeleneksel ambalaj :

PlywoodAkış Hortumu Aşınma Test Cihazı 3 İstasyonlu Eşzamanlı Test IEC60335-2-2 Uyumlu Ekipman

Ürün Tanıtımı

HJ0615, akış hortumlarının aşınma direncinin nicel değerlendirmesini elde etmek için standart test prosedürlerini ve akıllı ölçüm ve kontrol teknolojisini kullanır:

▎IEC standart hassas simülasyon sistemi

Hareket yörüngesi replikasyonu: Krank mekanizması, IEC60335-2-2 Şekil 101 test modeline uygun olarak, hortum ucunu 30r/dak sabit bir hızla yatay olarak 300 mm ileri geri hareket ettirir ve günlük kullanımda elektrikli süpürge ve çamaşır makinesi gibi ekipmanların hortumlarının sürüklenme ve aşınma sahnelerini geri yükler.

Aşındırıcı ve yük kontrolü: Standart ISO 6344-2'ye uygun P100 korindon aşındırıcı bant (0,1 m/dak. düzgün hareket), 1 kg dikey yük ile (tamburun merkezinden maksimum 600 mm), manuel testlerde tutarlılık sapmasını önlemek için sürtünme kuvvetini hassas bir şekilde kontrol eder.

▎Çok istasyonlu verimli tespit

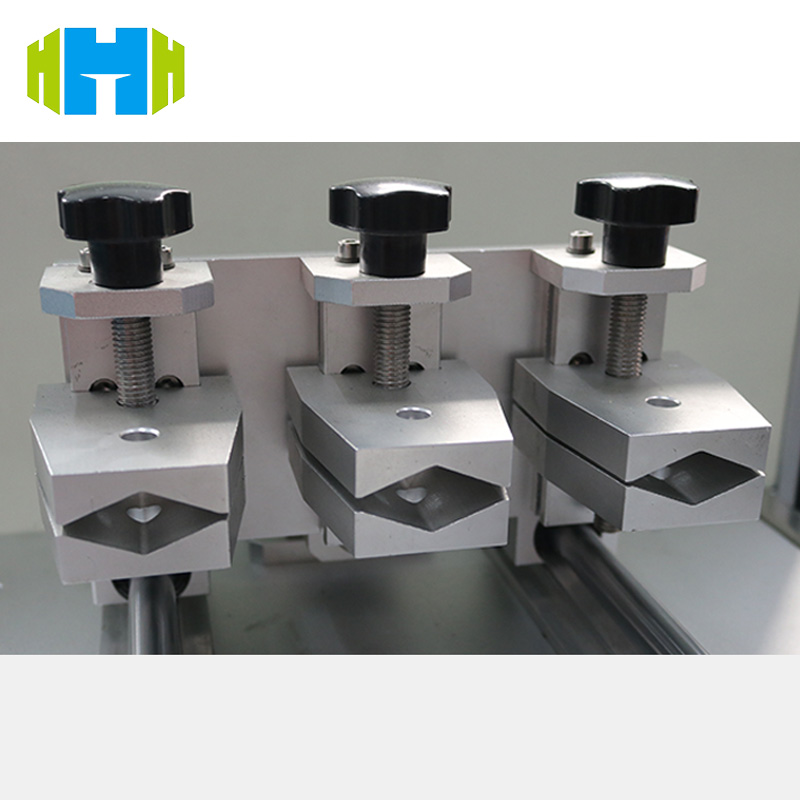

3 istasyonlu senkron çalışma: 3 bağımsız test istasyonu, farklı özelliklerdeki hortumların (çap 10-50 mm) aynı anda tespitini destekler, tek bir cihazın günlük işleme kapasitesi 300+ adettir, bu da büyük ölçekli seri üretim örnekleme ihtiyaçları için uygundur ve verimlilik, tek istasyonlu ekipmanlara kıyasla %200 oranında artırılır.

Hızlı geçiş tasarımı: Hızlı serbest bırakma kelepçesi hortum montajını 5 dakika içinde tamamlar (G1/4"-G3/8" arayüzüne uyarlanmıştır) ve Dyson ve Haier gibi markaların spiral boruları ve körükleri gibi karmaşık yapılarla uyumludur.

▎Akıllı ölçüm ve kontrol ve güvenlik koruması

Otomatik çalışma: 7 inç dokunmatik ekran, test parametrelerini (döngü sayısı, hız, yük) önceden ayarlar, IEC standart test sürecinin tek tuşla başlatılmasını destekler ve sürtünme süreleri ve aşındırıcı bant ömrü gibi 20'den fazla veriyi gerçek zamanlı olarak görüntüleyerek parametre ayarlama süresini %50 oranında kısaltır.

Arıza teşhisi:

Dahili iletken performans sensörü, hortum izolasyon katmanında hasar (kaçak akım>10mA) veya aşındırıcı bant kopması tespit ettiğinde otomatik olarak durur ve alarm verir ve veri verimliliği >%99'dur.

▎Yapısal tasarım ve dayanıklılık

Donanım yapılandırması: 300 mm ileri geri hareket doğruluğunu sağlamak için alüminyum alaşımlı kılavuz raylı (doğruluk ±0,1 mm) yüksek hassasiyetli adım motoru (hız hatası ±0,5r/dak); ek sürtünme girişimini azaltmak için paslanmaz çelik silindir (yüzey pürüzlülüğü Ra≤0,8μm).

Çevresel uyumluluk: Tamamen kapalı koruyucu kapak (koruma seviyesi IP54), aşındırıcı tozları izole eder, 0-40℃ oda sıcaklığında ve %10-%90 RH nem ortamında uzun süreli çalışmayı destekler ve kutup soğuğu/nemli sıcak bölgelerdeki laboratuvar ihtiyaçları için uygundur.

Ürün Özellikleri

IEC60335-2-2 Madde 21.102 ile tam uyumlu, CNAS bölümleriyle uyumluluk raporları yayınlayan, doğrudan CE/CCC sertifikasyonu için kullanılan

3 istasyonlu eş zamanlı test, tek ekipman günde 300'den fazla hortumu işler ve yıllık bir milyon ev aleti üretimi yapan üretim hatlarının tam muayene gereksinimlerine uyum sağlar

Krank hızı ±0,5r/dak, aşındırıcı bant hızı ±0,01m/dak doğruluk, ISO 9001 sertifikalı laboratuvar tarafından kalibre edilmiştir

Çıkarılabilir aşındırıcı bant modülü (değiştirme zamanı) <(yaklaşık 3 dakika), P80/P120 gibi aşındırıcıların birden fazla spesifikasyonuyla uyumlu, farklı test koşullarını karşılar

İletken performansının gerçek zamanlı izlenmesi + aşırı yük koruması, yalıtım hasarı nedeniyle oluşan elektrik çarpması riskinin önlenmesi ve test güvenliğinin %40 oranında artırılması

Uluslararası referans standartları

IEC 60335-2-2:2020 "Ev ve benzeri elektrikli cihazların güvenliği Bölüm 2-2: Elektrikli süpürgeler ve su emen temizlik cihazları için özel gereklilikler" Madde 21.102: Akım taşıyan hortumlar için aşınma testi yöntemi (Şekil 101 Krank mekanizması test modeli) Madde 16.3: Yalıtım hasarından sonra elektriksel dayanıklılık testi (2500 V dayanım gerilimi doğrulaması).

ISO 6344-2:2018 "Kaplanmış aşındırıcılar Bölüm 2: Aşındırıcı parçacık boyutu sınıflandırması", tutarlı sürtünme katsayısını sağlamak için P100 korindon aşındırıcıyı (parçacık boyutu 150-180 μm) belirtir.

Test nesneleri ve test öğeleri

Test nesneleri

Elektrikli süpürge akım taşıma hortumu (iletken tip/yalıtımlı tip).

Su emici temizlik ekipmanları için su besleme borusu (PVC/kauçuk malzeme).

Çamaşır makinesi su giriş borusu/tahliye borusu (yüksek basınç hortumu).

Mutfak aletleri için esnek boru (örneğin kahve makinesinin su giriş borusu).

Test öğeleri

Aşınma direnci: Aşındırıcı bant sürtünmesinin 100 katı sonrasında yalıtım tabakasının kırılma oranı, 300.000 çevrimden sonra iletken dirençteki değişim (≤%5 nominal değer).

Yapısal dayanıklılık: Krank ileri geri hareketi sırasında hortumun bükülme yarıçapı (≥20mm), birleşim yerlerinde yorulma çatlağı tespiti (mikroskop gözlemi).

Güvenlik performansı: kırılma sonrası elektriksel dayanıklılık (arıza olmadan 2500Vdc/1dk), kaçak akım (≤10mA).

Çevresel uyumluluk: Düşük sıcaklık - 20℃ aşınma direnci testi (%20 çevrim sayısında azalma kararı), sıcak ve nemli ortamda aşınma oranı karşılaştırması (60℃/%95 RH).

Teknik Parametreler

| Kategori | Parametre Ayrıntıları |

| Örnek | HJ0615 |

| Test İstasyonları | 3 iş istasyonu (eş zamanlı çalışma, bağımsız sayım) |

| Krank Hızı | 30r/dak (Doğruluk: ±0,5r/dak, önceden ayarlanabilir 20-40r/dak) |

| Yatay vuruş | 300mm (karşılıklı mesafe, hata: ±1mm) |

| Aşındırıcı Bant Hızı | 0,1 m/dak (ISO 6344-2 P100 korindon aşındırıcı bant) |

| Test Döngüleri | 0-999.999 döngü (önceden ayarlanabilir, 1 döngü çözünürlüğü, tamamlandığında otomatik durma) |

| Yük kütlesi | 1kg (dikey yük, silindir merkezinden maksimum mesafe: 600mm) |

| Hortum Çap Aralığı | 10-50mm (Elektrik süpürgesi hortumları, çamaşır makinesi boruları vb. ile uyumludur) |

| Kontrol Sistemi | PLC + 7 inç dokunmatik ekran (Çince/İngilizce arasında geçiş yapılabilir, gerçek zamanlı parametre eğrisi gösterimi) |

| Güç Kaynağı | AC220V±10%/50Hz, anma gücü: 5kW (kaçak koruması ile) |

| Çalışma Ortamı | Sıcaklık: 0-40℃; Nem: %10-%90RH (yoğuşmasız) |

| Koruma Sınıfı | IP54 (ana ünite), IP43 (test odası, toz geçirmez tasarım) |

| Boyutlar | 1000×900×1100mm (U×G×Y, koruyucu kapak ve karşı ağırlık sistemi dahil) |

| Ağırlık | 100kg (alüminyum alaşımlı çerçeve + paslanmaz çelik silindir) |

| Veri Depolama | 64 GB dahili depolama (100.000'den fazla test verisini destekler, CSV/PDF formatında USB aktarımı) |

| İletişim | RS485/Modbus TCP (uzaktan izleme ve fabrika sistemi entegrasyonunu destekler) |

SICAK ETİKETLER :