Bu ekipman, Guangzhou Hejin Automation Control Technology Co., Ltd tarafından Çin Ulusal Elektrikli Aparat Araştırma Enstitüsü için özelleştirilmiştir. Esas olarak, üretim kalitesini ve verimliliğini artırmayı amaçlayan bölünmüş hava kremi buharlaştırıcılarının ve kondansatörlerinin kuru sızıntı tespiti için kullanılır.

Öğe Hayır. :

HJ-APAT-006Minimum Sipariş Miktarı (MOQ) :

1 setÖdeme yöntemi :

L/C,T/T,PayPalFiyat :

NegotiatableÜrün oranı :

TurkiyeTedarik Yeteneği :

1 sets per 2 monthKurşun zamanı :

60 Working DaysGeleneksel ambalaj :

Plywood

Teknik Parametreler:

Parametre | Şartname | Değer |

Güç Kaynağı | Güç Kaynağı Voltajı: 380V/50HZ, <82KW | - |

İş parçasıyla ilgili Parametreler | İş Parçası Adı: Split - tip makine kondansatörleri ve buharlaştırıcıları İş Parçası İç Hacmi: 5L'den az (Yüksek basınç tankı helyum hacmi aynı anda 20 iş parçasını doldurabilir) | 4L |

Vakum Odası Kaçak Dedektörü Parametreleri | Minimum tespit edilebilir sızıntı oranı: 3,5*10 - 11Pa.m3/s Maksimum giriş basıncı: 300Pa Tepki süresi: 1 saniyeden az | 3,5*10 - 11Pa.m3/s 250Pa 0,8s |

Başvuru alanı:

Vakum Odası Parametreleri:İç Ölçüler: Y850G1200D350 (20 mm kalınlığında çıkarılabilir bölme ve bölmenin üstünden ve altından yüksekliği 590 mm'dir) Adet: 2 İç Hacim: 357L Kapı Açma ve Kapama Yöntemi: Asansör tipi kapı, kutunun dışından İş Parçası Giriş ve Çıkış Yöntemi: Manuel

Test Parametreleri:Büyük Sızıntı Testi Basıncı: 2,0 - 4,0 MPa (giriş basıncı için elektrik temaslı basınç göstergesi göstergesi ve filtrasyon cihazı ile) Helyum Doldurma Basıncı: 0,90 - 1,3 MPa sızıntı tespiti Doğruluk: 1 gram/yıl Ön tahliye Vakum Derecesi: ≤1000Pa Geri Kazanım Vakum Derecesi: ≤1000Pa Helyum Geri Kazanım Oranı: ≥%98 Helyum Kontrol Konsantrasyonu: ≥%80 Doğru Tespit Oranı: ≥%99,5。Değer:3,0 MPa 1,1 MPa - 800 Pa 900 Pa %99 %85 %99,8

Döngü Süresi:Büyük sızıntıyı kontrol edin (1 sistem, 1 kanal): 20 saniye/kanal (parça başına 20 saniyeyi karşılar) Tahliye ve helyum doldurma istasyonu (1 sistem, 1 kanal): 18 saniye/parça Vakum odası istasyonu: tek odacık başına 90 saniye (10 saniyelik manuel süre dahil), iki odacıklı bağlantıyla odacık başına 45 saniye, karşılar < 22,5 saniye/parça Kurtarma istasyonu (1 sistem, 1 kanal): 20 saniye/kanal.Değer:20s 18s 20s (iki bölmeli operasyonda parça başına) 20s

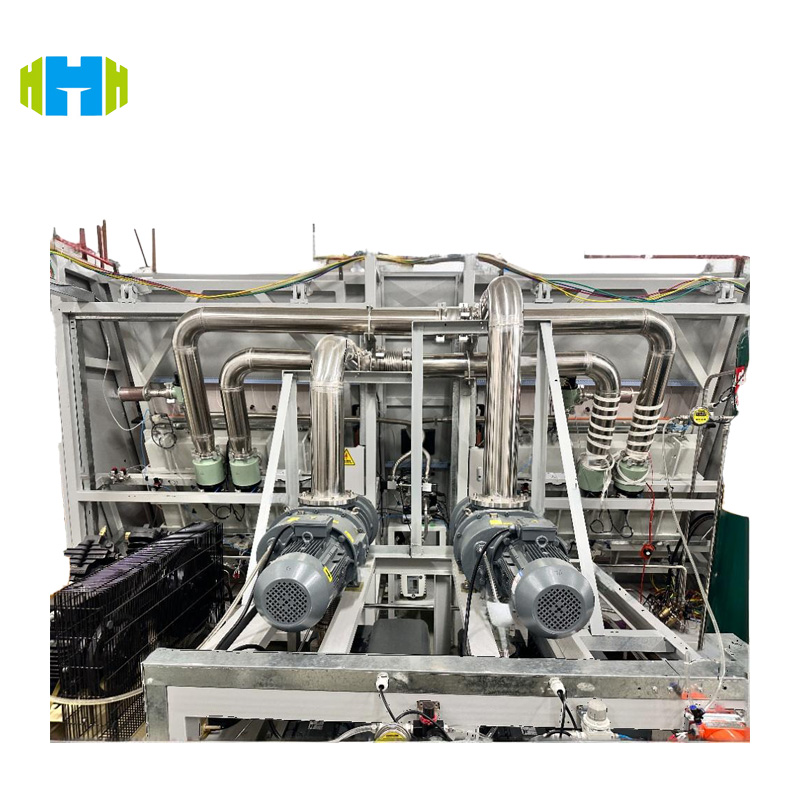

Ana Bileşenler:İş parçası kaçağı - tespiti, tahliyesi ve helyum - doldurma sistemi: iş parçası tahliye pompası SV25 (Leybold, 2 set), valf bankası tertibatı (Hejin, 2 set), vb.

Vakum odası ve kaçak dedektörü parçası: kaçak dedektörü (INFICON, 1 set), ana çıkarma pompası (Edwards vakum pompası ünitesi, 2 set), vb.

Kurtarma kısmı: düşük basınç tankı (1 takım), yüksek basınç tankı (1 takım), vb.

Elektrik kontrol parçası: PLC (Mitsubishi, 1 set), dokunmatik ekran (Mitsubishi/Weinview, 1 set), vb.

Ekipmanlarımız en yüksek endüstri standartlarına sıkı sıkıya bağlı kalarak tasarlanmış ve üretilmiştir. Ekipmanın istikrarını ve güvenilirliğini sağlamak için yüksek kaliteli malzemeler ve gelişmiş üretim teknikleri kullanarak titiz bir kalite kontrol sürecine bağlı kalıyoruz. Her bileşen, performans beklentilerini karşılamak veya aşmak için dikkatlice seçilir ve titizlikle test edilir.

Sonuç olarak, Buharlaştırıcılar ve Kondenserler için Vakum Odası Helyum Kaçak Tespiti Ekipmanımız, klima üretim sektöründe oyunun kurallarını değiştiriyor. Gelişmiş teknolojisi, yüksek hassasiyetli performansı, verimli iş akışı ve olağanüstü satış sonrası hizmetiyle, ürün kalitesini artırmak, üretim verimliliğini iyileştirmek ve pazarda rekabet avantajı elde etmek isteyen üreticiler için ideal bir seçimdir. Bugün ekipmanımıza yatırım yapın ve üretim sürecinizde yaratabileceği farkı deneyimleyin.

SICAK ETİKETLER :