Relay Helyum Kütle Spektrometrisi Kaçak Dedektörü, elektrikli araç endüstrisi için özel olarak tasarlanmış yüksek hassasiyetli bir test cihazıdır. Zorlu ortamlarda otomotiv rölelerinin ve elektronik bileşenlerinin mutlak güvenilirliğini sağlamak için dünyanın lider helyum kütle spektrometrisi kaçak tespit sistemini kullanır.

Öğe Hayır. :

HJ146Minimum Sipariş Miktarı (MOQ) :

1 setÖdeme yöntemi :

L/C,T/T,PayPalFiyat :

NegotiatableÜrün oranı :

Türkiye,ChinaTedarik Yeteneği :

1 sets per 90 daysKurşun zamanı :

90 Working DaysGeleneksel ambalaj :

PlywoodRöle Helyum Kütle Spektrometresi Sızıntı Dedektörü

Ürün Tanıtımı:

Elektrikli araç üreticileri ve elektronik bileşen tedarikçileriyle yaptığımız çalışmalarda, "conta güvenilirliğinin" ürün kalitesi açısından öneminin farkındayız. Bu, sıradan bir makineden çok daha fazlasıdır; ürününüzün güvenliğinin koruyucusudur.

Bu helyum kütle spektrometresi kaçak dedektörü, kullanıcı dostu bir tasarıma sahiptir. Test sürecini elektrikli araç endüstrisinin üretim hızına özel olarak optimize ederek test verimliliğini önemli ölçüde artırdık. Yüksek hızlı üretim hatlarında bile, her bileşenin contasının otomotiv sınıfı standartlarını karşıladığından emin oluyoruz. Mükemmel test ekipmanlarının üretim verimliliğini artıran bir unsur olması gerektiğine, bir darboğaz olmaması gerektiğine inanıyoruz.

HJ146, HJ Test System'in kaçak tespit teknolojisindeki 20 yıllık deneyimini miras almaktadır. Her tasarım detayı, elektrikli araç sektörünün benzersiz ihtiyaçlarını anlamamızı yansıtır. Ürettiğiniz her bileşenin, elektrikli araçların güvenilir çalışması için hayati önem taşıdığının farkındayız.

Ürün Özellikleri:

Otomotiv sınıfı hassasiyet testi: En katı otomotiv elektroniği güvenilirlik standartlarını karşılar

Yüksek hızlı otomatik çalışma: Elektrikli araç endüstrisinin seri üretim ihtiyaçları için özel olarak tasarlanmıştır, hızlı test ve veri analizine olanak tanır

Hızlı başlatma ve yanıt: Cihazın başlatma süresi 2 dakikanın altında ve yanıt süresi 0,5 saniyenin altındadır; üretim hattı ritimlerine uyum sağlar

Çoklu sızıntı tespit modları: Çeşitli elektronik bileşenlerin test ihtiyaçlarını karşılamak için vakum, koklama ve pozitif basınç sızıntı tespit modlarını destekler.

Uluslararası Referans Standartları:

IEC 60068-2-17: Uluslararası Elektroteknik Komisyonu Standardı "Çevresel Testler Bölüm 2-17: Sızdırmazlık Testleri"

ISO 16750-3: Karayolu Taşıtları — Elektrikli ve Elektronik Ekipmanlar için Çevresel Koşullar ve Testler — Bölüm 3: Mekanik Yükleme

ISO 9001:2015: Kalite Yönetim Sistemi Standardı, tüm ürün süreci boyunca tutarlı kaliteyi garanti altına alır

Teknik Parametreler:

| Proje | Parametreler |

| İş İstasyonu Sayısı | 8 |

| Boyutlar | 2000mm*2500mm*2000mm |

| Üretim Oranı | 500 adet/saat |

| Ortam Sıcaklığı | 0-40°C |

| Güç Kaynağı | 380V, 3 fazlı, 5 kablolu, 50Hz |

| Güç Tüketimi | 5kW |

Ürün Uygulamaları:

Elektrikli Araç Endüstrisi: Pil yönetim sistemi rölelerinin, şarj sistemi rölelerinin ve tahrik sistemi kontrol rölelerinin test edilmesi

Otomotiv Elektroniği: Elektronik kontrol ünitelerinin (ECU), sensörlerin ve konnektörlerin sızdırmazlık performansının sağlanması

Elektronik Bileşen Üretimi: Minyatür kapalı röleler, transformatörler ve indüktörler gibi bileşenlerin sızıntı oranının test edilmesi

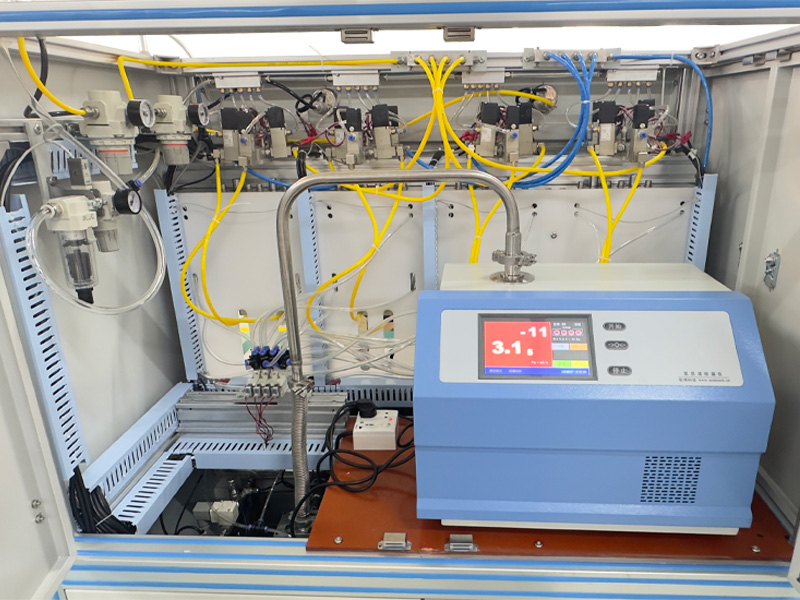

Detay resimleri:

SICAK ETİKETLER :